Saturday, 26 January 2013

transfer of shape measurements to plywood panels

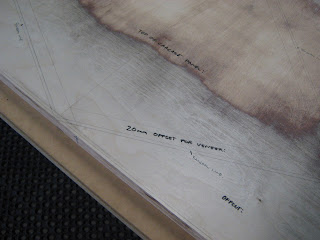

Transferring the measurements of the drawer bases to rough cut plywood panel. The part includes a 20mm offset which runs around the whole base. After that there is a 5mm offset. On the 5mm offset line I will be cutting it on the band saw. Once that is done than the whole 5mm offset will be cut off with the circular saw with the guide trench bar. This will than just leave the 20mm offset for veneering and the final size panel shape.

Its best to cut off the major off cut first because when coming to the exit cut on the circular saw there would be too much weight due to the off cut falling from the part. This can cause major tear out especially at the sharp corner sections.

Im looking at purchasing a Festool TS 55mm R plunge cutsaw. I have other circular saws at home but they are not very accurate more just for rough stuff. I have used this one in my early years in the furniture design course I did before the apprenticeship. This one isn't too bulky to use. There is a larger circular saw I have looked at as well by Festool by I don't need to buy that one since its larger and too expensive compared to this one plus the work I'm doing I don't need such a huge blade for.

Whats great about this saw is that its sort of a combination between a circular saw and a drop saw when making the plunge cut. One of the major features I also like about this saw is the guide trench. This will allow me to obtain a very accurate cut especially when i come to doing the final cutting after the veneering.

I will also have to buy some new blades for it used for cutting specially manufacture board. Also splinter guard.

The smaller and less gaping between the teeth and the more qty of teeth will give you a finer cut. Although these blades I'm getting would not be suitable for cutting solid timber. There are many different blades to choose from it really depends on what job your doing. Will explain this later down the track since I will be using a lot of different blades for specific jobs for my final piece.

I don't need to do to mark all the measurements out on all the drawer box bases. All I need to do is mark out one cut it to the veneer offset overhang than I can use this as a template to transfer part shape onto the other plywood panel parts.

Will be doing this for all the other parts that are more than 1 qty.

When doing this mark out areas that are going to be offcuts. Mark out for band saw line and label it. Mark/ label out where your 20mm offset veneer overhang is and where the circular saw cut is going to be made. Also mark out the finished panel section for when the 20mm offset needs to be cut off. Yeah this will be covered over with veneer and will need to be marked out again but doing it here as well will show you what you have to play with if a mistake is made.

Again making sure that your placing the shape transfer in the right direction that the grain is running in. Some parts are obvious where its going but others are the same size in length and width.

Transferring image to front door panels. Again only need to do one than will use as template for the other.

Try to make different sized strips for transferring measurements. Becomes a lot quicker compared to a ruler and quite useful when transferring sizes to unusual shapes like the diamond arrow head shape panel for the top. I used these strips to mark out the 20mm offset section and the 5mm offset section. I used these strips for parts of my life scale drawings so I can trust that they are accurate since I have used them before. I try not to use solid timber templates unless I oil them. This is due to shrinking and expansion. But if your doing a project where your doing to use the template heaps make the template out of thin piece of polypropylene or use mdf and seal it than mark them.

One thing to remember when doing measurement transfers and life scale drawings is to try and use the same brand of rulers as your others. Like obtain the same brand for your 150mm, 300mm 600mm 1000mm and 2000mm. This is because different brands will vary slightly. There are some very good companies that sell measuring devices perfect for this kind of stuff which ill tell you later down the track. As well check these rulers to your tape measure before you buy them. If your serious with your trade buy a good quality tape measure. This will be one of the most common measuring tools you use. The old saying pay for what you get.

You pay for shit tools you will get a shit result. But also the other saying dont blame the Ferrari just because your arse cant drive. This means you invest in good quality tools make sure you know how to use them properly and take care of them properly.

Transferring shape for back doors onto plywood panels.

Transferring shape for drawer box lids onto plywood panels

Transferring shape for top panel section of cabinet onto plywood panel.

Ill have to wait for the Ikebana panel and the drawer box panel since I'm still in the process of repairing them. Also will have to wait for the top cabinet carcass panel and the base panel since they are two pieces that are going to be laminated. Will need to wait till I go back to tafe (which i start in about a week) since ill be using their veneer press. Work doesn't have one. I have been thinking of getting one for my work shop but at the moment can not afford it and can not afford to wait for it to be shipped in.

Images for Ikebana base panel.

This is the amount of the small part section connection that will be left when the whole shape is cut out.

Transfered the image of the Ikebana base to the plywood panel. Since the top drawer base panel is the same dimensions I will just cut this one out than use it as a template after having 5mm offset cut off from circular saw.

Again like the others labeling off cut sections and band saw lines so not to make mistakes.

Transfered the part image shape to the top carcase panel, ready for band sawing.

The left over layer from the sanding wont matter too much most of it is in the waste sections and is only about .1 to .2mm in thickness which wont be a huge drama.

Following the same steps as the other panels. Have been noticing that some of the angles are a little bit out which has thrown out some of the measurements. This is ok since I have plenty of waste from the 20mm offset for veneering. When coming to remove this I think ill be getting new measure equipment. Like with sailing if out by 1 deg or half a deg from starting point to end point can throw things out totally. So its really important that I get these angles totally right.

I'm thinking of buying new measuring equipment from a company called Incra http://www.incra.com/product_tsf_main.htm Great company for measuring tools. Like I said before use a brand that you trust and only use that brand.

transfered the part image of the cabinet base to laminated panel. I used some of the Incra measuring equipment on this. I'm thinking of looking further into this and seeing if there are measuring devices from Incra that go up to the 600mm and 1000mm mark.

I have been thinking and it would be wise to get good quality templates made for the finished sizes for the diamond shaped parts. I'd like to get them CNC due to accuracy. I have been noticing that if out by the slightest degree or mm can throw out everything.

So this would mean I would need the following templates.

Cabinet base.

Ikebana base

Top drawer base (same as Ikebana base)

Top carcass panel

Top panel.

I was thinking of writing up a program and getting it done on the Nesting machine at work just on some 3mm MDF sheeting. We have a lot of this at work since we get it in as protective sheets for the other veneered boards we order in.

Final size drawn in along with 20mm veneer offset and 5mm offset.

Ready to use a already cut panels as a template for the other repeated panels. In this selection it included the Ikebana base panel which shares the same sized shaped as the top drawer box panel. The front and back doors and drawer box lids and the drawer box bottoms.

First image transfer for one of the drawer box lids complete. Making sure the image transfer is still going in the right grain direction.

Drawer box lids 4 in total (including the one that is already cut)

Transfered all the drawer box bottoms, four in total including the one that is already cut out. Again making sure image is placed in right grain direction.

Transferring image to top drawer box panel from Ikebana panel.

Adding in 5mm offset.

Adding in 5mm offset to doors after image transfer.

Parts now have their 5mm offset drawn in and are now ready to be cut out. I'm thinking of cutting out the smaller parts on the scroll saw in my work shop and than using either the band saw at tafe or work to cut out the larger parts. My band saw for my work shop has not come in yet.

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment